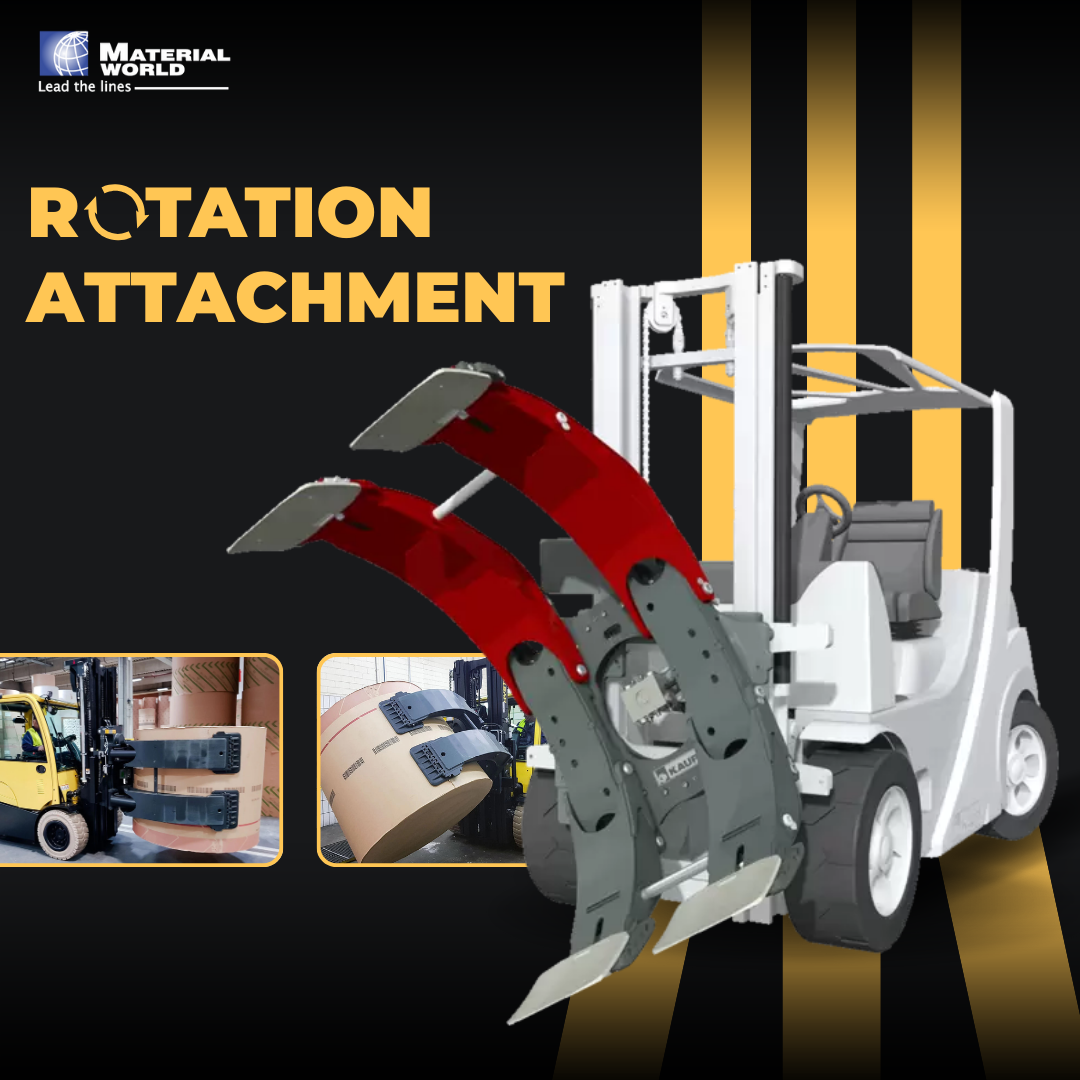

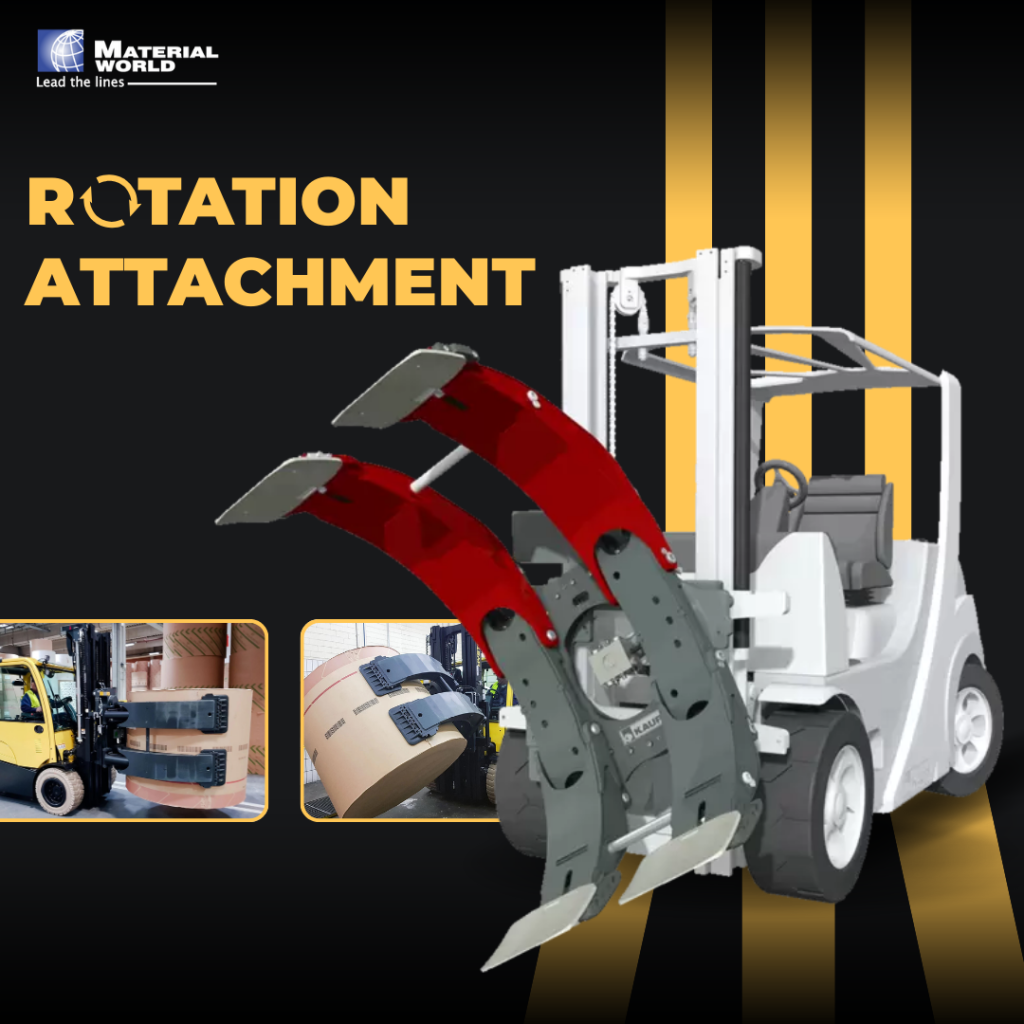

Forklift Rotation Clamp – Advanced Solution for Efficient and Safe Roll Handling

In modern industries such as paper manufacturing, steel processing, packaging, printing, and logistics, handling heavy cylindrical loads requires high precision, safety, and operational efficiency.

A forklift rotation clamp is a specialized forklift attachment designed to securely grip and rotate rolls, allowing operators to tilt, dump, and accurately position cylindrical loads during material handling processes.

Compared to standard forklift forks, rotation clamps significantly improve productivity while minimizing product damage and workplace risks.

How Does a Rotation Clamp Work?

A rotation clamp is mounted directly onto the forklift via:

-

Standard ISO / FEM mounting systems

-

The forklift’s hydraulic circuit

Operating Process:

-

The forklift approaches the roll

-

Clamp arms securely grip the roll surface

-

Hydraulic pressure stabilizes the load

-

The rotating mechanism allows 90°, 180°, or 360° rotation

-

The roll is placed precisely in the required position

This process ensures smooth, controlled, and safe handling, even for heavy or delicate rolls.

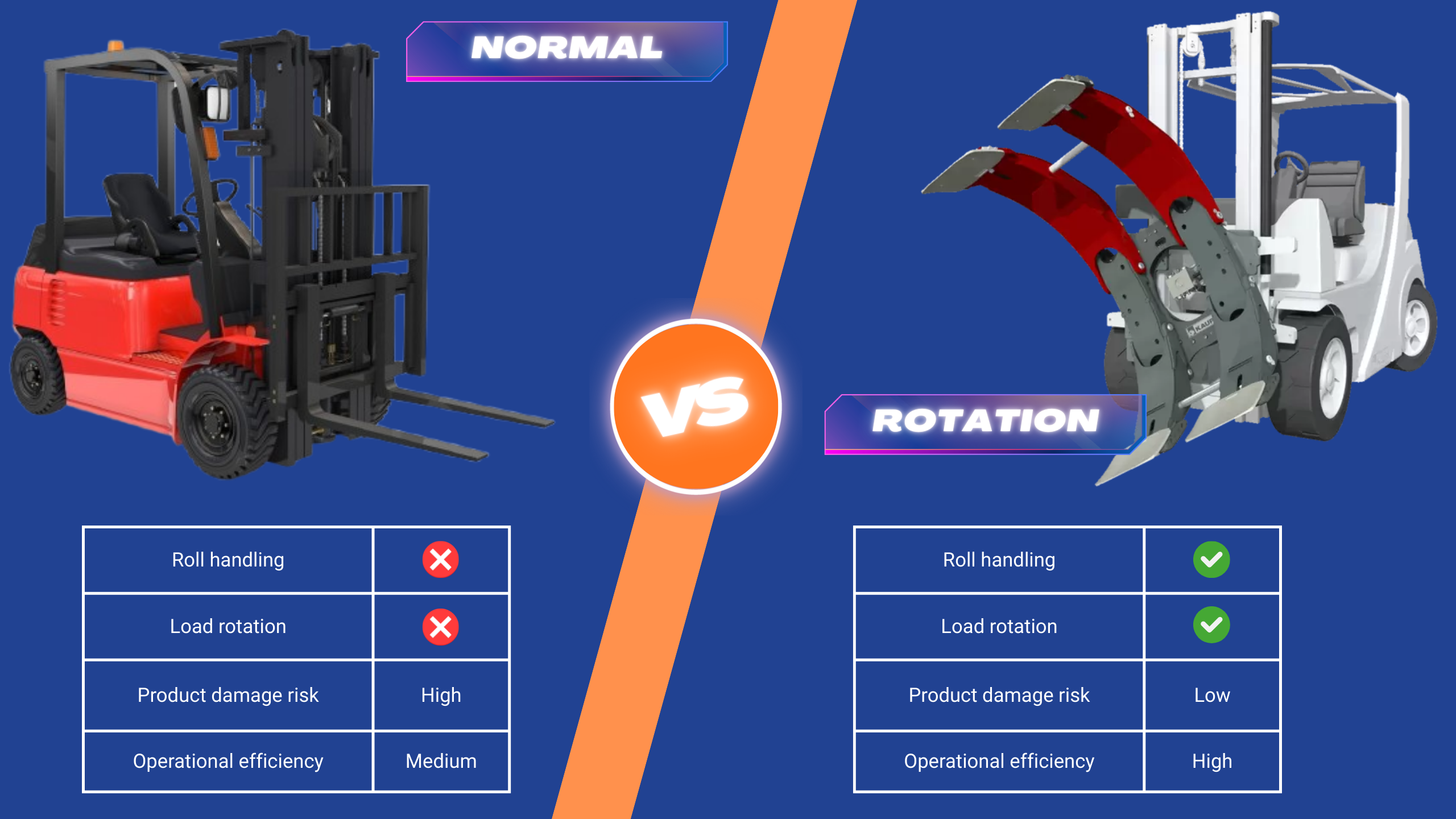

Rotation Clamp vs Other Forklift Attachments

Rotation Clamp and Standard Forks

Rotation clamps are ideal for operations requiring frequent roll rotation or precise orientation.

Key Benefits of Forklift Rotation Clamps

Precise Roll Rotation & Positioning

-

Accurate alignment for production lines

-

Easy transfer between vertical and horizontal positions

-

Reduced rehandling and downtime

Reduced Product Damage

-

Prevents dents, crushing, and tearing

-

Protects paper, film, and coated materials

-

Minimizes product loss and customer claims

Improved Workplace Safety

-

Reduced manual handling

-

Lower risk of roll dropping accidents

-

More controlled and stable operations

Long-Term Cost Efficiency (ROI)

Although rotation clamps require a higher initial investment:

-

Labor costs are reduced

-

Product damage is minimized

-

Handling speed is increased

Typical ROI is achieved within 12–24 months in high-frequency roll-handling operations.

Common Applications of Rotation Clamp Attachments

Rotation clamps are widely used in:

-

Paper mills and packaging plants

-

Steel coil warehouses

-

Printing and converting facilities

-

Logistics and distribution centers

-

Export and industrial storage operations

Forklift Rotation Clamp Market Price Overview

Prices in Vietnam

Pricing depends on:

-

Forklift capacity

-

Roll size and weight

-

Required rotation angle

-

Brand and country of origin

Reference price: ~VND 180 million – 500+ million per unit

Global Market Pricing

USD 7,000 – 20,000+ per unit

Fast ROI through efficiency gains and reduced damage

How to Choose the Right Rotation Clamp

When selecting a forklift rotation clamp, consider:

-

Roll material and surface condition

-

Maximum load capacity

-

Required rotation angle

-

Compatibility with existing forklifts

-

Technical support and after-sales service

Material World Asia provides:

-

Customized rotation clamp solutions

-

Professional technical consultation

-

Installation and maintenance support

-

Integrated material handling solutions

Designed to meet real-world operational requirements in industrial environments.

Can rotation clamps be used on all forklifts?

✔ Yes, provided the forklift meets hydraulic and capacity requirements.

Does a rotation clamp reduce forklift lifting capacity?

✔ Slightly, due to attachment weight, but always within safe operating limits.

Can clamps be customized for specific roll types?

✔ Absolutely. Custom designs are available.

MW

Blog Category

Latest

-

Material Handling Solutions for Different Types of Goods Material handling solutions tailored for differ...

Material Handling Solutions for Different Types of Goods Material handling solutions tailored for differ... -

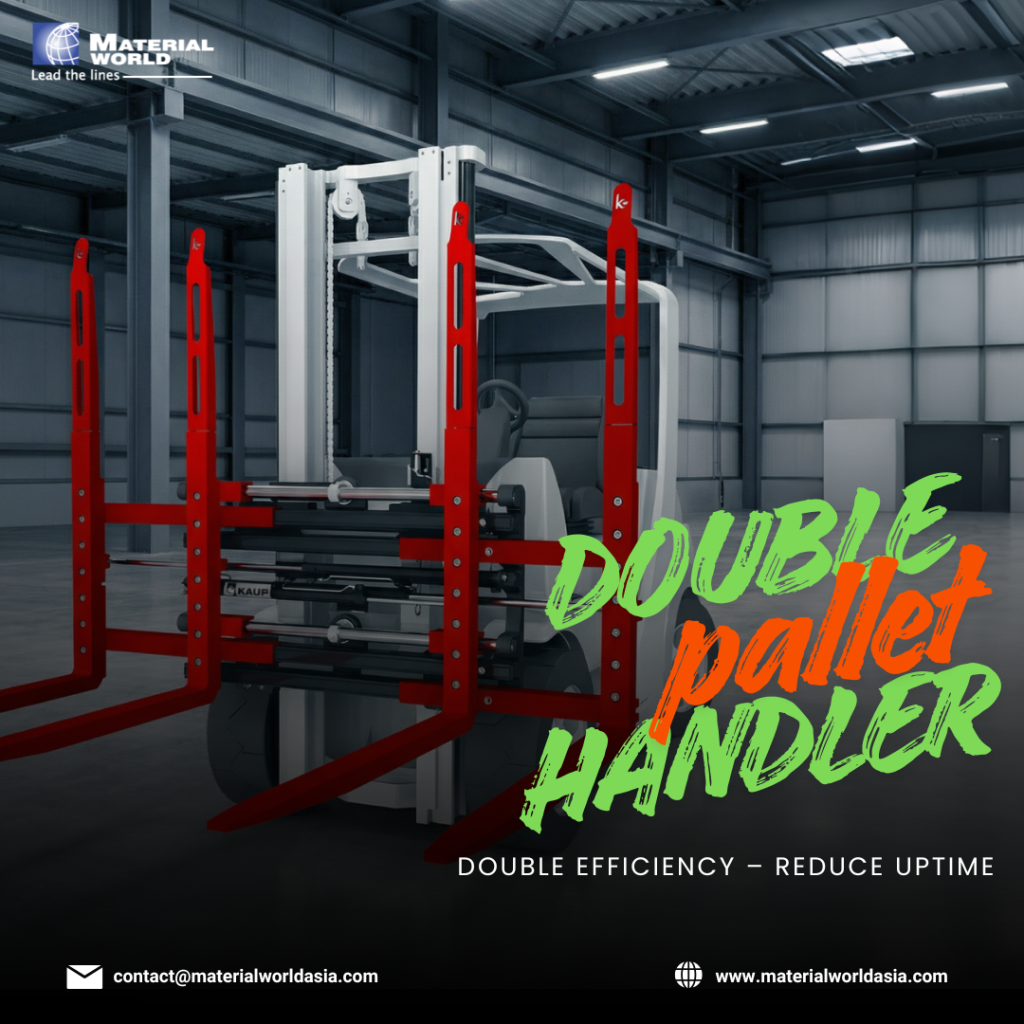

Double Pallet Handler – Boost Warehouse Productivity with Dual Load Handling A Double Pallet Handler is a forklift attachmen...

Double Pallet Handler – Boost Warehouse Productivity with Dual Load Handling A Double Pallet Handler is a forklift attachmen... -

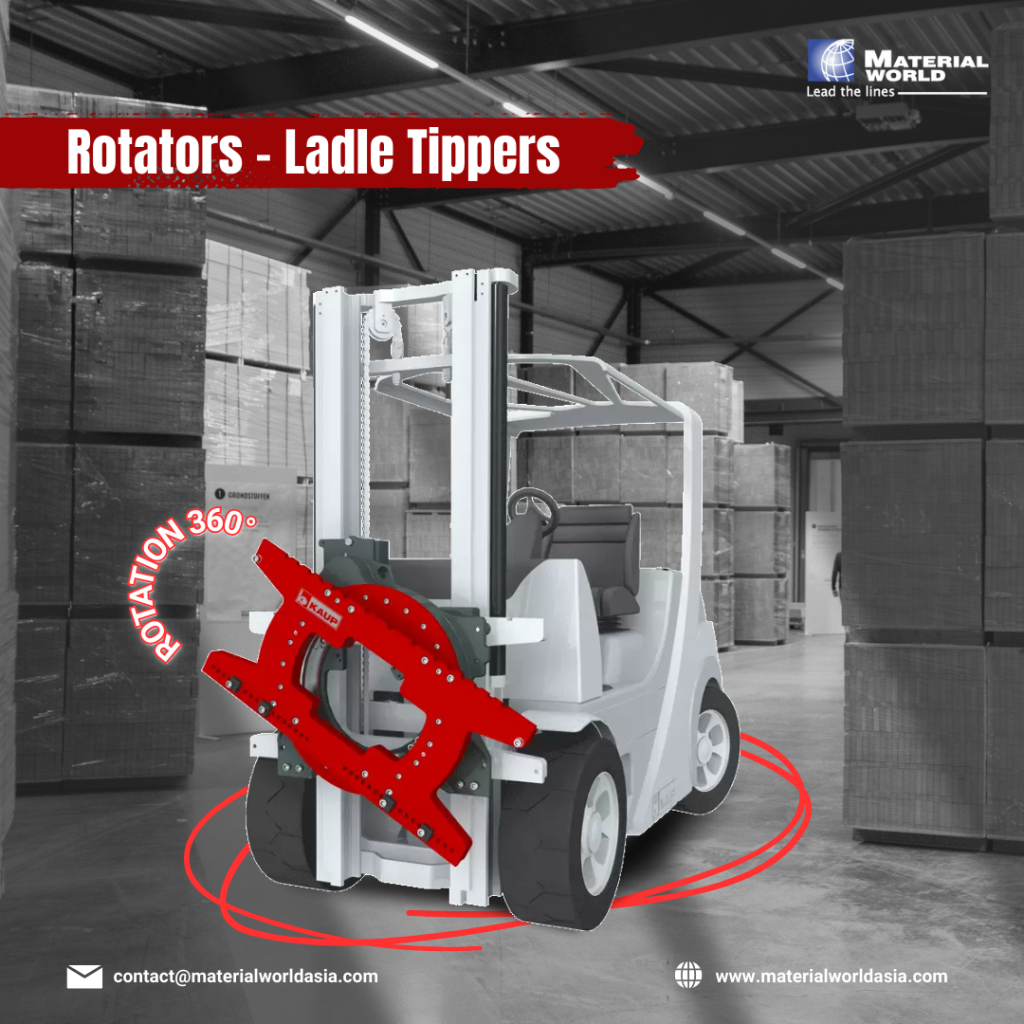

Rotators – Ladle Tippers: Safe & Efficient Container Tipping Solutions Rotators – Ladle Tippers are specialized forkli...

Rotators – Ladle Tippers: Safe & Efficient Container Tipping Solutions Rotators – Ladle Tippers are specialized forkli... -

Forklift Rotation Clamp – Advanced Solution for Efficient and Safe Roll Handling A forklift rotation clamp is a specialized atta...

Forklift Rotation Clamp – Advanced Solution for Efficient and Safe Roll Handling A forklift rotation clamp is a specialized atta... -

Push / Pull Forklift Attachment – Essential Solution for Slip Sheet Handling Push / Pull forklift attachment is the essentia...

Push / Pull Forklift Attachment – Essential Solution for Slip Sheet Handling Push / Pull forklift attachment is the essentia...