Why Solid Fiber Slip Sheet is Gaining Popularity — A Smart Replacement for Wooden Pallets

In modern logistics and warehousing operations, companies are increasingly looking for ways to reduce costs, minimize storage space, and streamline handling processes. Traditional wooden or plastic pallets have long been the standard — but they come with drawbacks: heavy weight, high material cost, storage and return logistics, treatment requirements (like ISPM-15 for export), and risk of contamination, pests, or damage.

That’s where Solid Fiber Slip Sheet comes in — a thin but strong sheet designed to replace pallets while offering significant advantages in cost, efficiency, and sustainability. According to the product page, Solid Fiber Slip Sheet from Material World Asia provides a lighter, space-saving, and rodent- or insect-free alternative to pallets.

WHAT IS SLIP SHEET?

A slip sheet (or slip-sheet pallet sheet) is a flat panel — typically made from solid fiberboard, kraft paper layers, or other recyclable board material — with dimensions similar to a pallet footprint. Unlike bulky pallets, slip sheets are thin, light, and disposable or recyclable.

Common materials: solid fiberboard, kraft linerboard, sometimes plastic (HDPE or PE).

Slip sheets are used with special forklift attachments (push-pull or roller forks) that grip the sheet and lift the load, making them functionally equivalent to pallets in loading/unloading operations.

Key Benefits of Using Solid Fiber Slip Sheet

Cost Savings — Lower Material & Handling Cost

-

According to data from manufacturers, a solid fiber slip sheet can cost ~ US-$1.00 per sheet, while a wooden pallet typically costs US-$6.00–12.00 each. That’s 6–12× cheaper.

-

Reduced weight and volume lead to lower shipping costs, especially for export logistics.

Space & Storage Optimization — Thinner, Lighter, More Efficient

-

Slip sheets are only 1–3 mm thick, compared to ~100–150 mm for pallets, allowing many more sheets to be stored in the same warehouse space.

-

It’s common that 100–200 slip sheets take up less volume than a single pallet.

Increased Logistics Efficiency & Labor Reduction

-

Loading/unloading time is drastically reduced — what might take several workers many hours manually can be done by one forklift operator in minutes with slip-sheet + push-pull system.

-

No need to return pallets, track pallets, repair or sterilize pallets — simplifies supply chain and saves administrative overhead.

Hygiene & Safety, Lower Risk of Contamination or Pest Infestation

-

Slip sheets eliminate use of wood — no nails, no wood splinters, no risk of insect or rodent infestation.

-

For export shipments, slip sheets avoid phytosanitary treatment requirements (like ISPM-15), reducing cost and complexity.

Environmental & Sustainability Benefits

-

Many slip sheets are recyclable and made from renewable resources — paperboard or recyclable plastic — reducing carbon footprint vs. wood pallets.

-

Lightweight and compact — reduces fuel consumption per load, increases loading efficiency per container/truck — helps lower CO₂ emissions.

Slip Sheet made from recycled materials helps protect the environment

Potential Limitations / Considerations

While slip sheets present many advantages, there are a few limitations to keep in mind:

-

Requires forklifts with push-pull or roller-fork attachments to handle slip-sheet pallet loads — this is an initial investment.

-

For heavy, extremely dense loads or irregular-shaped loads, traditional pallets may still offer better structural support (depending on application).

-

If slip sheets are made from fiber board/paper — moisture resistance must be considered (or use plastic slip sheets) to avoid weakening.

Nevertheless, for the vast majority of palletized goods, slip sheets offer an optimal balance of cost, efficiency, and convenience.

Solid Fiber Slip Sheet from Material World Asia — Product Overview & Why You Should Consider It

Solid Fiber Slip Sheet from Material World Asia is an advanced pallet alternative designed to reduce shipping and storage costs, minimize pest/rodent contamination, and eliminate maintenance or repair costs typical for wooden pallets.

Main advantages:

-

Cost-effective — significantly cheaper than wooden pallets.

-

Saves warehouse space and storage volume.

-

Reduces insect/rodent infestation risk — no wood, no nail, no splinter.

-

No need for pallet return, repair or ISPM-15 treatments.

-

Easy disposal or recycling after use.

-

Compatible with many types of loads and easy to handle with standard forklift + push-pull attachment.

Product Link: [Solid Fiber Slip Sheet – Material World Asia]

Which Industries & Use Cases Benefit Most?

Solid Fiber Slip Sheet is ideal for:

-

Warehouses and distribution centers handling palletized goods.

-

Consumer goods, food, beverage, packaged goods — where hygiene and cost efficiency are priorities.

-

Export shipping — as slip sheets avoid wood-pallet phytosanitary regulations.

-

Logistics companies, freight forwarders, exporters/importers.

-

Manufacturing plants packing boxed goods, metal parts, plastic items, etc.

-

Retail & wholesale distribution centers needing efficient stacking and loading/unloading.

MW

Blog Category

Latest

-

Material Handling Solutions for Different Types of Goods Material handling solutions tailored for differ...

Material Handling Solutions for Different Types of Goods Material handling solutions tailored for differ... -

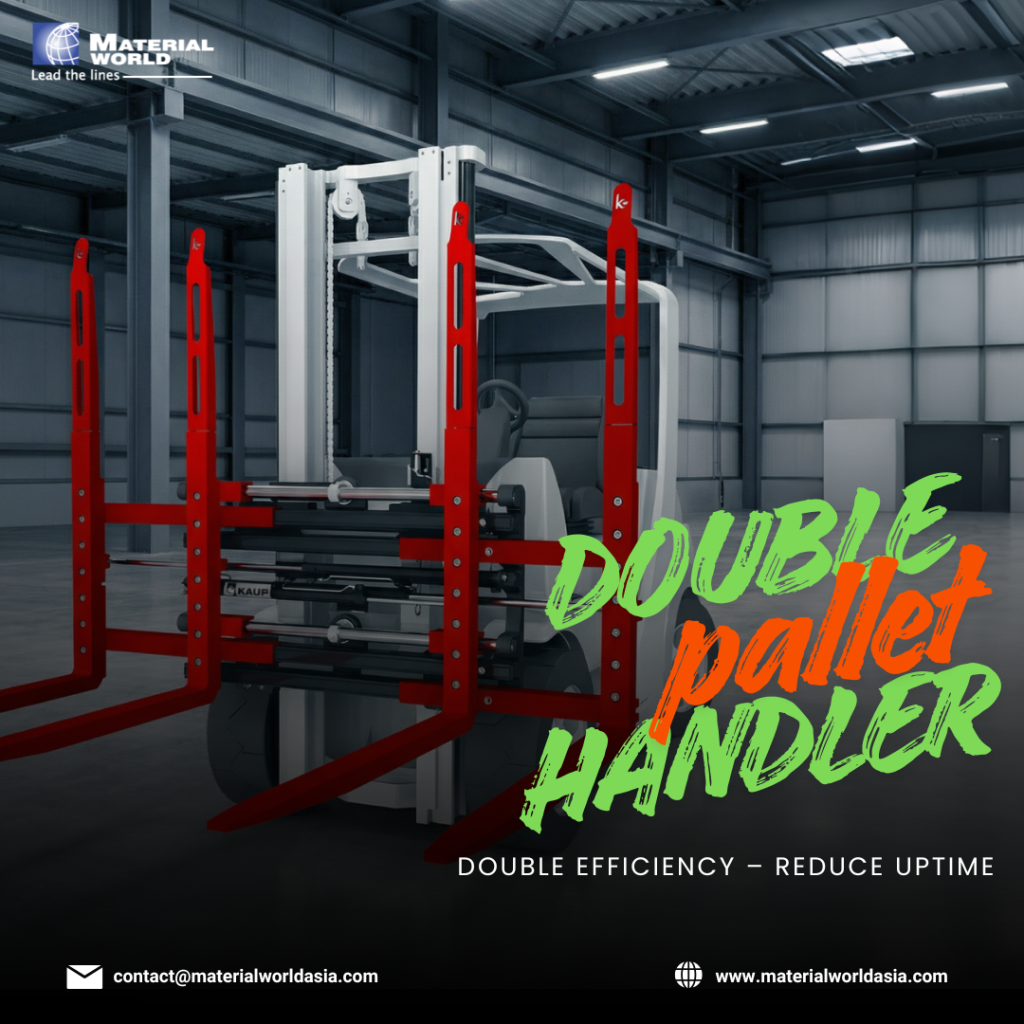

Double Pallet Handler – Boost Warehouse Productivity with Dual Load Handling A Double Pallet Handler is a forklift attachmen...

Double Pallet Handler – Boost Warehouse Productivity with Dual Load Handling A Double Pallet Handler is a forklift attachmen... -

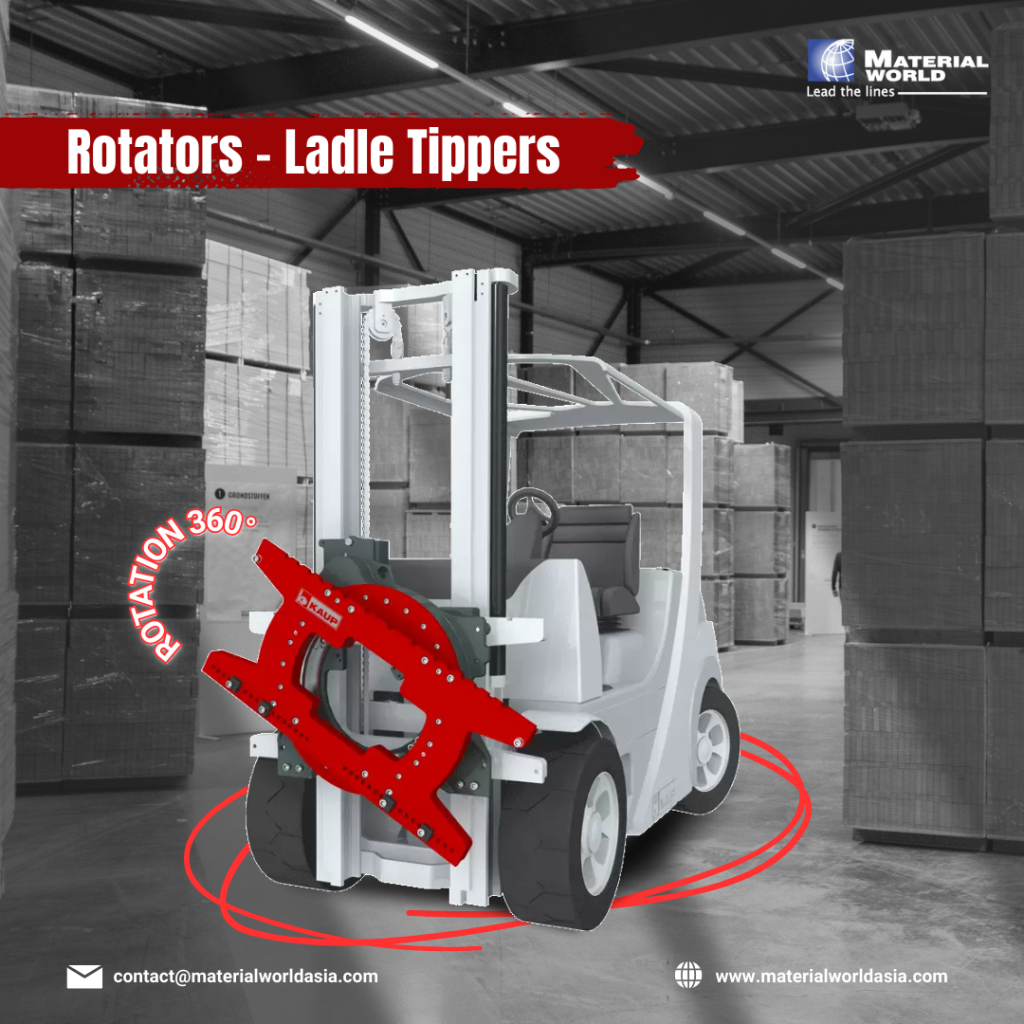

Rotators – Ladle Tippers: Safe & Efficient Container Tipping Solutions Rotators – Ladle Tippers are specialized forkli...

Rotators – Ladle Tippers: Safe & Efficient Container Tipping Solutions Rotators – Ladle Tippers are specialized forkli... -

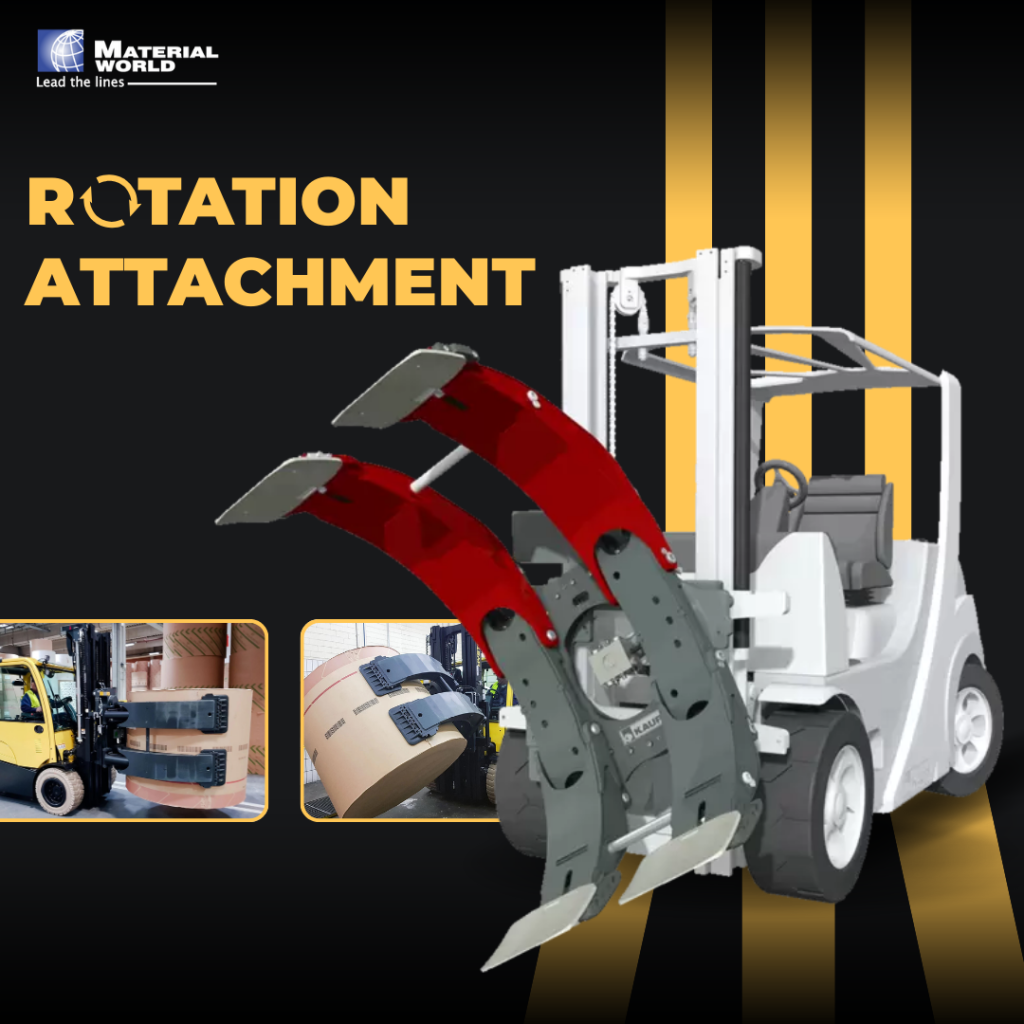

Forklift Rotation Clamp – Advanced Solution for Efficient and Safe Roll Handling A forklift rotation clamp is a specialized atta...

Forklift Rotation Clamp – Advanced Solution for Efficient and Safe Roll Handling A forklift rotation clamp is a specialized atta... -

Push / Pull Forklift Attachment – Essential Solution for Slip Sheet Handling Push / Pull forklift attachment is the essentia...

Push / Pull Forklift Attachment – Essential Solution for Slip Sheet Handling Push / Pull forklift attachment is the essentia...